Understanding the Advantages of a China Rapid Prototyping Factory

In the contemporary manufacturing industry, the demand for rapid prototyping has surged, particularly in metal fabrication. Companies across various sectors are realizing the importance of prototyping in product development. A China rapid prototyping factory is emerging as a pivotal player in this arena, offering exceptional services that can significantly enhance business outcomes. This article delves into the myriad benefits of collaborating with a rapid prototyping factory in China, emphasizing its role in accelerating product development and improving competitiveness in the market.

The Rise of Rapid Prototyping in Manufacturing

Rapid prototyping refers to the fast fabrication of a scale model of a physical part or assembly using 3D computer-aided design (CAD) data. It is pivotal in modern manufacturing for several reasons:

- Speed: Rapid prototyping allows manufacturers to produce prototypes in a matter of days rather than weeks or months.

- Cost-Effectiveness: Reducing the time to market directly correlates with lower overall costs.

- Enhanced Design Flexibility: Designers can easily modify prototypes and conduct testing to ensure the final product meets customer needs.

Why Choose a China Rapid Prototyping Factory?

China has become synonymous with manufacturing efficiency, quality, and competitive pricing. Choosing a China rapid prototyping factory offers several unique advantages:

1. Cost-Effectiveness

One of the foremost reasons businesses turn to Chinese factories is the cost advantage. The operating costs in China are typically lower than in Western countries, enabling businesses to save significantly on prototype production. This cost-saving translates into more budget-friendly product development processes.

2. Advanced Technology and Expertise

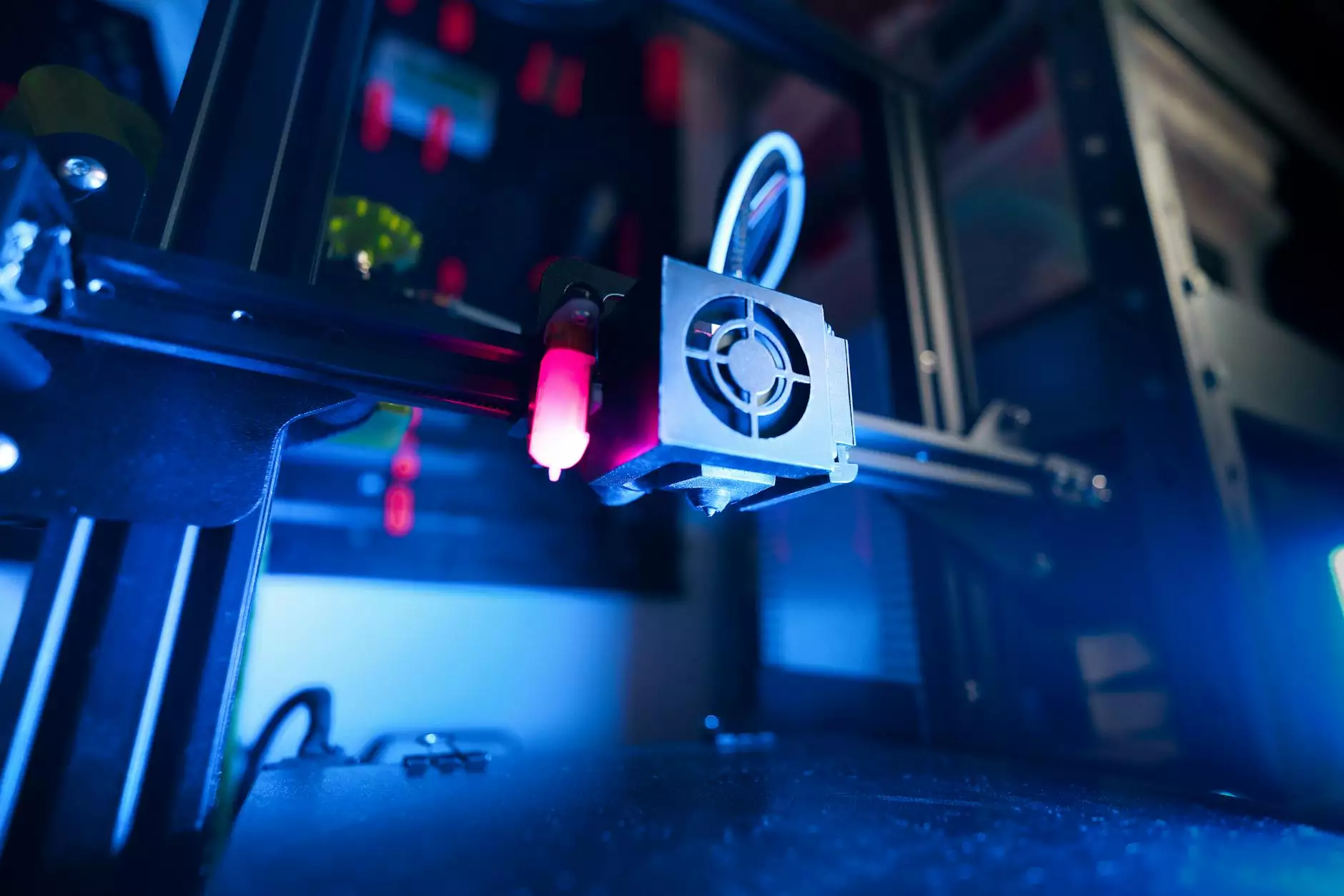

Chinese rapid prototyping factories employ cutting-edge technologies, such as:

- SLA: Stereolithography, which is ideal for creating highly detailed parts.

- SLS: Selective Laser Sintering for strong, durable prototypes.

- 3D Printing: Various methods that cater to different materials and applications.

These technologies are complemented by skilled professionals who are proficient in both the tools and industry trends, ensuring that your prototypes meet high standards.

3. Shorter Lead Times

Speed is critical in today’s fast-paced market. A reputable China rapid prototyping factory can drastically reduce lead times, allowing businesses to iterate quickly and effectively. Quick prototyping means companies can test, modify, and finalize designs in record time, enhancing their ability to respond to market demands.

4. Scalability and Flexibility

Another remarkable advantage is the scalability of operations in China. Whether you need a single prototype or a small batch of parts for validation, Chinese factories have the capabilities to adjust their production processes. This flexibility helps businesses align their prototypes with varying project sizes and specifications.

Industries Benefiting from Rapid Prototyping

The applications of rapid prototyping are vast and span multiple industries:

- Aerospace: Custom components and testing for aviation technology.

- Automotive: Designing and testing parts and assemblies.

- Medical: Creating surgical models and medical devices.

- Consumer Electronics: Quick iterations on gadgets and devices for faster launch times.

By leveraging a China rapid prototyping factory, businesses in these fields can enjoy unparalleled advantages in product development.

Ensuring Quality in Prototyping

Quality control is paramount when it comes to prototyping and manufacturing. Here’s how a reliable China rapid prototyping factory ensures quality:

- Quality Assurance Programs: Factories adhere to international standards and have rigorous QA protocols to ensure every prototype is meticulously checked.

- Skilled Labor: A highly trained workforce ensures that the manufacturing processes are executed flawlessly.

- Material Quality: Sourcing high-quality materials is critical in ensuring that the prototypes meet the needed specifications and performance standards.

How to Select the Right China Rapid Prototyping Factory

Choosing the right factory is crucial. Here are steps to consider:

- Research: Investigate potential factories online. Look for reviews and testimonials from previous clients.

- Request Samples: Before committing, ask for samples of previous work to assess quality.

- Evaluate Communication: Effective communication is essential for successful collaboration. Ensure the factory is responsive and understands your needs.

- Check Certifications: Valid certifications such as ISO can indicate a factory’s commitment to quality control.

The Future of Rapid Prototyping in China

As technology continues to advance, the future of rapid prototyping in China looks promising. The integration of AI, machine learning, and advanced materials will likely enhance the speed and efficiency of prototyping services. Surface machining techniques and additive manufacturing are evolving, allowing for even more complex parts to be produced at an unprecedented pace.

Conclusion

Utilizing a China rapid prototyping factory can provide substantial advantages for businesses seeking to streamline their product development processes. The combination of cost savings, technological innovation, shorter lead times, and scalability positions Chinese factories as leaders in the manufacturing sector. Adopting rapid prototyping not only enhances design flexibility but also empowers businesses to navigate the complexities of modern markets successfully.

By partnering with a top-tier factory like Deep Mould, companies can elevate their design and manufacturing capabilities, ensuring a robust product development cycle that meets the demands of today’s competitive landscape.